Sid A.; Oct. 16th, 2020

I have made many mistakes in my designs. I thought that putting up checklists that try to catch these mistakes before they happen for various designs might be useful for both those of us at FutureScape and for readers. This is the first of what I hope will be numerous posts regarding one of these “design checklists”. This one in particular focuses on DC-DC converter design. Please note that the following is definitely not comprehensive.

- Big Picture Decisions

- Step up or step down?

- Choose: Low-dropout regulator, Inductor-based buck/boost, Charge-pump buck/boost, or something else?

- Voltage Levels

- Check that Input voltage range is adequate

- Check that Output voltage range is adequate. This applies to both fixed and adjustable DC-DC Converters

- Check that any logic IO levels (such as enable pins) are good

- Current levels

- Check that the circuit you have designed can supply enough current

- Check that the transient conditions for the circuit are OK

- If you are using an inductor-based design, make sure to double check inductor saturation

- Check that the decoupling capacitance you have is enough and that the capacitors have good characteristics (ESR,ESL, etc.)

- Make sure that your capacitors are close to the pins in the layout

- Temperature

- Check that the circuit will not heat beyond acceptable levels (especially important for high currents, large voltage steps, and LDOs)

- Make sure to go back and check voltages and currents to account for heating, if this is a concern!

- Add heatsinking to layout if needed

- Noise

- Calculate ripple and verify that it is within acceptable limits

- If needed modify design to include segmented grounds, add decoupling capacitors, and add second-stage LDOs as needed to reduce noise

- Protection

- Consider whether you need reverse-current/voltage protection, under/over voltage protection, over-current protection, etc.

- Efficiency and power consumption

- Make sure that your circuit is optimized for your power requirements. Battery operated devices will need different characteristics here

- Remember to compute efficiency into your battery analysis!

- Cost

- Consider the cost of the IC, at specific volume, if this is a factor

- Remember: you pay for what you get. Try not to prioritize cost over quality

- Size

- Consider the size of your design. If size is a factor then consider switching from an inductor to inductorless/LDO design.

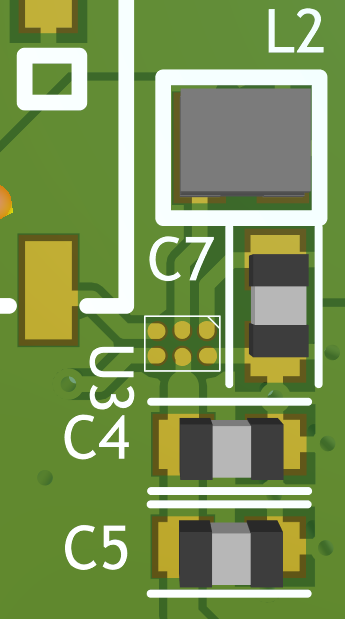

Featured Image: A design of an inductor-based boost converter that I recently did, optimized for low-cost, low-power, and small size. It costs only about $2 at single unit qty., is an average of 85% efficient with around 900nA total quiescent current, and has a board area of only 0.4in^2. It converts a battery voltage of 2.7-3V to 3.3V. IC used: TI TPS61099